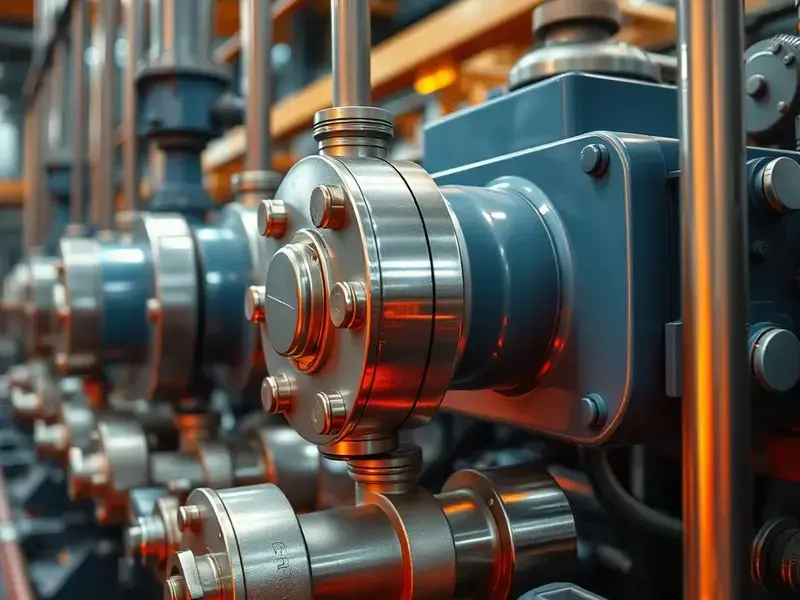

Industrial Pump Diagnostics & Repair

When your operation depends on fluid movement, we make sure it keeps moving. Accurate diagnostics, honest repairs, and rapid turnaround for all industrial pump types.

Call (308) 235-3883Comprehensive Repair Solutions

From small circulation pumps to massive centrifugal units, we have the expertise and inventory to fix it.

Advanced Diagnostics

We don't just replace parts—we find the root cause. Using vibration analysis, flow testing, and pressure monitoring, we pinpoint exactly what's affecting your pump's performance.

Mechanical Repairs

Worn bearings, damaged seals, corroded housings—we handle it all. Our workshop is equipped for machining, welding, and precision balancing to restore pumps to OEM specifications.

Motor & Electrical

Pump issues often stem from the motor or power supply. We troubleshoot electrical systems, replace burnt windings, and repair control panels to ensure reliable operation.

Refurbishment

Extending the life of your equipment is better for your bottom line. We offer full tear-down refurbishment, replacing wear components and repainting for a like-new finish.

Our Repair Process

1. Intake & Assessment

We document the issue, run baseline tests, and provide a detailed estimate within 24 hours.

2. Disassembly & Inspection

Teardown reveals hidden wear. We photograph every step so you see exactly what we're working on.

3. Repair & Reconditioning

Worn parts are replaced with quality components. We balance rotors and verify clearances before reassembly.

4. Testing & Delivery

Final hydro-test and run-cycle verification. We deliver and install it back into your system, ready to work.

Real-World Fixes for Real Problems

We've solved issues that shut down plants for days. Here are a few examples of challenges we've tackled for other Nebraska facilities:

Grain Processing Facility (Kearney)

Severe vibration in a high-capacity centrifugal pump. We discovered bearing failure due to misalignment. Realigned, replaced bearings, and rebalanced impeller—pump runs smoother than new.

Municipal Water Plant (Sidney)

Submersible pump clogging repeatedly. Inspections revealed damaged wear rings causing flow turbulence. Machined and restored wear rings, reducing flow resistance significantly.

Biofuel Refinery (York)

Chemical seal failure on a transfer pump. Upgraded to a more chemically resistant seal material and reinforced the gland packing. Stopped the leaks and improved safety compliance.

Need a Repair Quote?

Bring your pump to us or request an on-site visit. We provide upfront pricing so you know exactly what to expect.